Vacuum double glazing technology

Energy efficiency is a priority of the modern UK, the main goal of which is to reduce the amount of energy used while maintaining the same level of security, comfort in commercial and residential buildings.

The energy-efficient window market is growing rapidly in recent years and new glazing technology such as vacuum double glazing becomes more cost-effective than before.

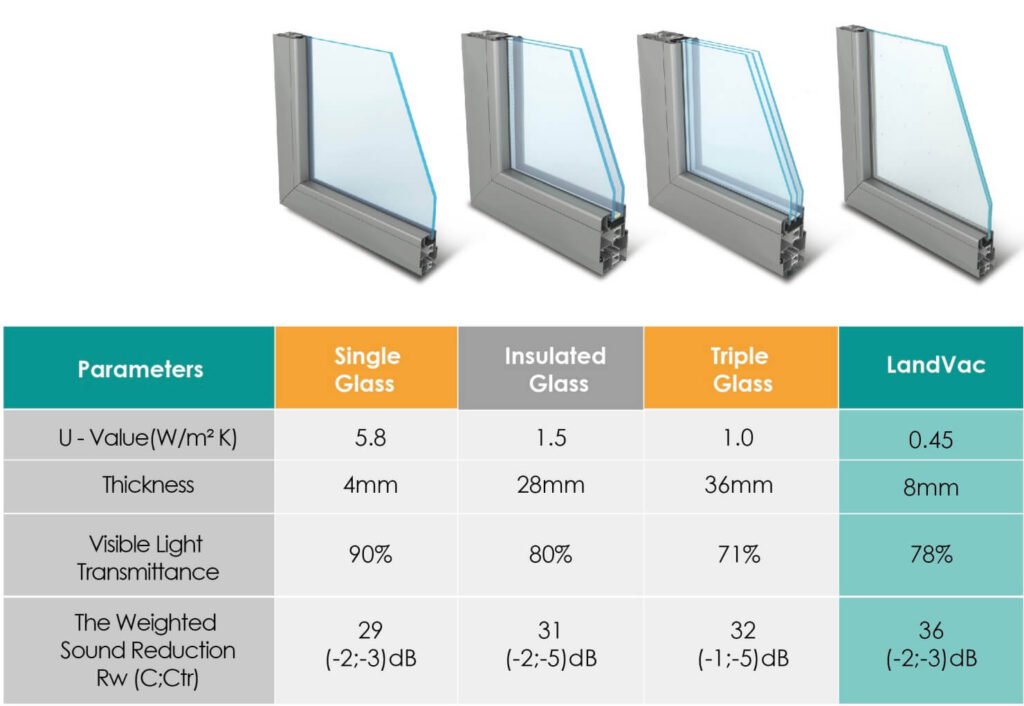

Since the glass represents about 80% of the window, its heat-insulating properties are responsible for the whole construction. Windows account for 10-30% of the heat loss of the building. Vacuum double glazing can reduce heat loss of single-glazed sash windows by 8 times.

The modern energy-saving glass units have achieved unbelievable results in heat insulation due to special low-emission coatings, inert gases inside the glass unit, qualitative sealing and warm spacer frames. Despite the achieved result, specialists in the industry of translucent structures continue to search for new solutions to improve the thermal insulation characteristics.

Many experts agree that the most promising innovation in the market is vacuum insulated double glazing units and our sash window refurbishment team agree with them.

The History of vacuum double glazing

Vacuum-insulated glass units are not an absolute novelty, for example, Pilkington Spacia™ was the first commercially available vacuum glazing back in the late 90s.

There have been discussions about this technology since the 90s of the last century. The technology of thermos production has pushed specialists to create vacuum glass units.

The first vacuum double-glazed window was developed by engineers of the University of Sydney.

In 1997, the first production of vacuum insulating glass was launched commercially. But certain complexities of the technology, as well as restrictions in the use of such double glazing units did not allow them to become widespread in UK and Europe.

In Germany, vacuum glass technology developments are funded at the government level and are called ProVIG. The work is being carried out by the Institute for Window Technology in Rosenheim. A complex production including, in particular, the development of new hermetic methods of connecting glass edges, the mechanical properties of the vacuum double-glazed window are being investigated.

Many scientists around the world are working on developing a profile system that will be sized to fit vacuum insulated glass units. It is likely that in the future, production technology will reach a new level.

Vacuum double-glazed windows design

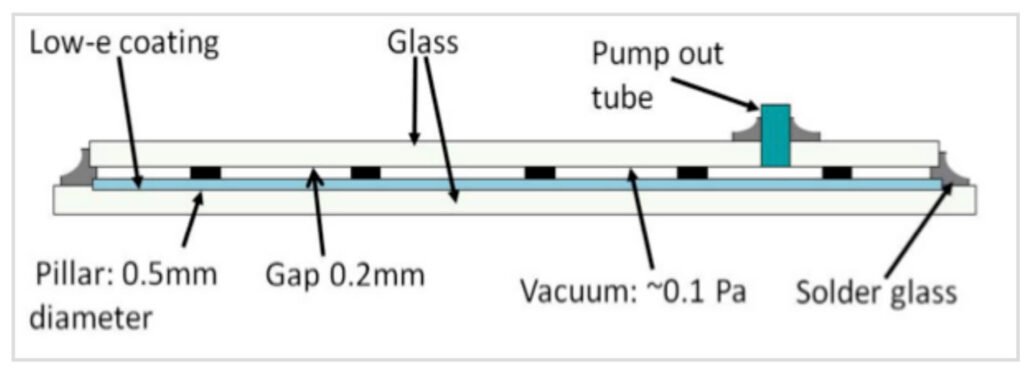

Vacuum double glazing is fundamentally different from standard gas-filled double glazing. Two panes of glass are located one millimetre apart. Air is removed from this gap.

In order to create a vacuum between the panes and to withstand the atmospheric pressure, small spacers are evenly inserted between the panes. The spacers have a minimum diameter of 0.5 mm, so they do not distort the view and do not decrease the light transmission. The spacers are only visible from a close distance on a light background.

Vacuum double glazing is perfect for sash window retrofitting

The advantages of vacuum double glazing units are the highest thermal and sound insulation properties, as well as significantly lower weight of the unit as a result those units can be used in double glazing retrofitting projects, even for windows in Grade 2 listed properties.

It is the reduced weight of the construction and the small width of the double glazing glass units that opened opportunities to save and re-use old sash window frames to improve thermal efficiency only by retrofitting new glass into the old rebates.

LandVac double glazing

LandVac has created a unique vacuum insulating double glazing. The company has R&D and a factory in China it’s vacuum double glazing products are predicted to have a great future. It consists of two or more panes of glass bonded to one another by staggered inserts (5 cm distance from each other). The inserts are up to 1 mm in diameter and up to 4 mm wide (the distance between the panes).

The LandVac glass unit uses tempered glass, which made the vacuum glass unit strong. The surface tension of the glass is 90 MPa and provides the highest strength and resistance to wind loads. The flexible edge bonding contributes to thermal resistance.

Combination of vacuum glass unit with regular gas-filled double glazing

Compared to other vacuum-insulated glass units, where the width of the vacuum chamber was minimal (1 mm), the width of the vacuum chamber was increased to 4 mm in this insulated glass unit. This width of the vacuum has resulted in almost zero heat transfer between the panes. The formation of condensation is excluded.

In addition, vacuum double-glazed windows have high sound insulation similar to acoustic glass, low and medium frequencies are practically not transmitted by the glass, and high frequencies are significantly dampened. The noise level is reduced by 39 dB.

LandVac offers the option of double-glazing in combination with a vacuum glazing unit. The design of such glazing is complicated, reminiscent of a sandwich: two glass panes with a vacuum connection – an air layer – another glass. The configuration and width of such glazing can easily replace standard triple-glazing with air or inert gas.

Vacuum double glazing thermal efficiency

Due to high thermal insulation properties, vacuum double-glazed windows allow significantly reduce bills on heating, ventilation and air conditioning of premises. The lower weight of the construction guarantees easy transportation and installation.

Of course, the high cost of production of such glass units is a disadvantage and slows down their mass use in UK homes. But undoubtedly, vacuum double glazing is recognized as a breakthrough in the glass market and as energy prices increase, more and more UK households will be looking for ways to increase the efficiency of their homes.