Sash windows draught proofing

If you find that cold draughts, rattling windows and external noises keep you from enjoying some of your rooms, then we would recommend that you consider draught-proofing as a cost-effective solution.

Sash windows can be draught stripped very satisfactorily, with the added bonus of reducing fuel bills, improving soundproofing and making the windows easier to operate.

Sash windows draught-proofing process

We take your sashes apart, cut grooves around the edges of the window and install a permanent draught seal. Seals are hidden from the eye and exclude draughts around the sash without affecting the window’s traditional appearance.

This decreases the heating needed, saving money on your energy bill!

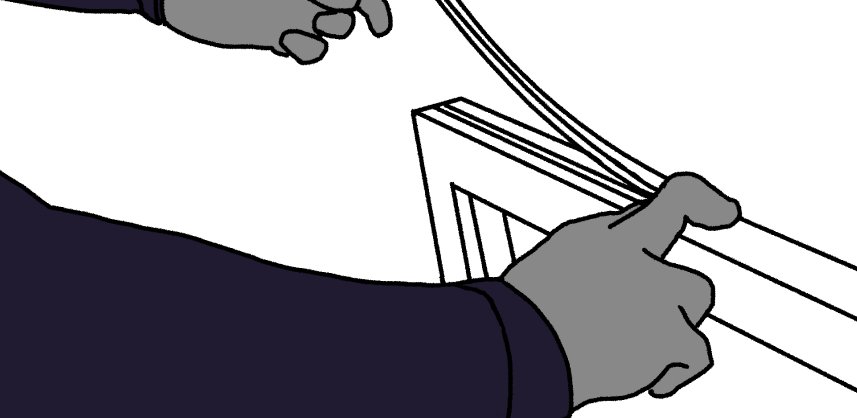

1. Sash windows grooved out

Prepare frames prior to installing the draught-proofing system (brush pile carrier)

2. Draught proofing system installed

Install a draught-proof system/ pile carrier

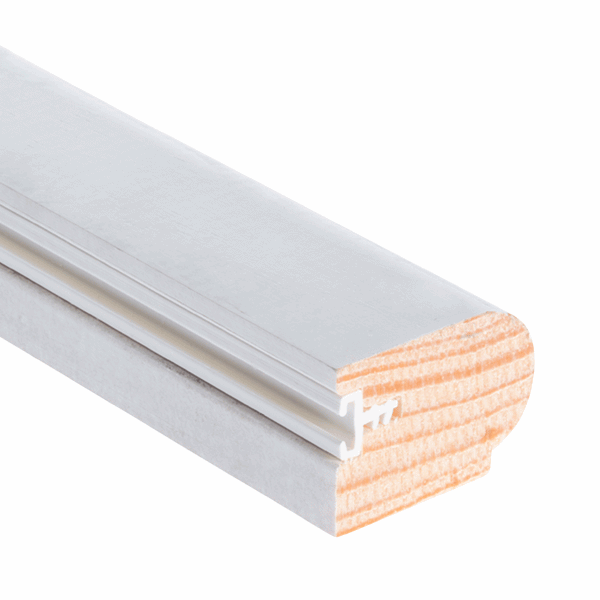

3. New Staff Bead installed

Install new Staff Bead/Parting bead with carrier pre-inserted.

Benefits of draught-proofing old sash windows

Sash windows draught-proofing cost

- Prepare frames prior to installing the draught-proofing system

- Install a new parting bead

- Replace the staff bead

- Replace or install a draught-proof strip to the top rail, meeting rail and bottom rail

| from £320 per window Draught-proofing is usually done as a part of the restoration of the full windows service package: it is vital to repair any damaged or rotten timber prior to draught-proofing |

Sash window draught proofing is more environmentally friendly than fitting new windows and can be installed for a fraction of the cost of complete replacement or double-glazed windows.

Homeowners often think single glazing is to blame for energy losses and overlook how much energy is lost due to cold air entering your home through gaps around windows.

Draught seals are hidden from the eye so as not to affect the look of a traditional window

Sash windows draught-proofing products

- Sashes are fully removed from the box frame for all required machining.

- All alterations will be made to achieve a smooth sliding action of both top and bottom sashes.

- Consumable windows components are to be renewed, such as staff beads, parting beads and sash cords.

Internal spaces become more comfortable and the functioning of windows can become much quieter. With more control over what air enters or escapes, draught-proofing can make the management of energy usage much easier, bringing financial and environmental advantages, year after year

Our draught exclusion strips are premium grade, providing long life using high-quality materials. They are fitted discreetly into parting bead, staff bead, top rail, meeting rail and bottom rail of your existing windows so that original designs and appearance are not compromised or impacted

We do not change the appearance of the window and eliminates all the common problems associated with older sash windows. All of the character and the features of the window are retained.

Draught proofing procedure:

- Virtually eliminates all draughts and dust ingress.

- ensures a smooth sliding of sashes.

- eliminates the rattling of sashes.

- reduces heating bills and improves energy efficiency.